SONOTRONIC GmbH

Becker-Goering-Str. 17-25

76307 Karlsbad, Germany

E-Mail: sales@sonotronic.de

Mon to Thu 8 am – 5 pm

Friday 8 am – 3 pm

Phone:

Ultrasonic washing

Environmentally friendly process with great effect

The ultrasonic process can be used in textile finishing to wash narrow fabrics as well as broad fabrics in an energy-efficient manner. The principle is based on the creation of cavities and the direct mechanical action of ultrasonic.

How does ultrasonic washing work?

In ultrasonic washing, the ultrasonic at 20 kHz acts directly on the tissue and mechanically beats the substances to be dissolved out of the tissue, so to speak. The particularly refined feature of ultrasonic washing is that the excess substances are not only loosened from the tissue purely mechanically, but also additionally by cavitation. The ultrasonic acting on the tissue generates periodic compression and expansion of the liquor absorbed by the tissue. Due to these pressure fluctuations, microscopic cavities form in the fluid. The subsequent implosion of these gas- and water vapor-filled cavitation bubbles leads to extreme conditions locally, so that shear forces are generated by the collapsing bubbles, which dissolve the excess substances from the tissue at high speed.

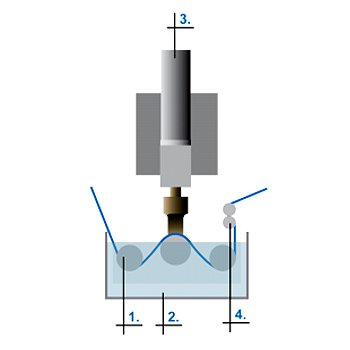

Via the feed (1), the fabric is fed into the basin (2), which is filled with slightly heated water, possibly enriched with detergent. Here, the fabric absorbs liquid in the form of the water. The vibrations transmitted by the ultrasonic unit (3) wash the sizing or spinning oils or the excess color particles out of the material with the water. During this process, the fabric is continuously guided between a roller, which serves as an anvil, and the sonotrode, the tool that mechanically transmits the ultrasonic. By subsequently directing the tissue into the water bath again, the dissolved substances are rinsed out. The squeeze roller at the take-off (4) ensures that the absorbed wash liquor is squeezed out in the fabric and transports the fabric to the next process step.

Depending on the type of fabric or degree of soiling, the process can be repeated in a second ultrasonic washing module directly connected to the first module. Simply passing through an ultrasonic washing module can replace several basins of conventional, high-temperature equipment.

The ultrasonic washing module from SONOTRONIC

Compared with conventional systems, the size of an ultrasonic washing system is only a quarter. As a result, there is automatically less material in the system during the process. Instead of up to 4-8 passes in the past, with ultrasonic washing it is sufficient for the material to pass through the system only 1-3 times, which has an extremely positive effect on process times and reduces water consumption by about half. Another advantage of ultrasonic washing over conventional processes is that virtually no warm-up time is required for the wash liquor or the die. This not only additionally shortens the process, but also contributes significantly to reducing energy consumption. To achieve comparable results in washing (washing efficiency), the ultrasonic system requires only about one-third of the energy of a conventional system.

The fact that the process itself is very efficient and environmentally friendly is also demonstrated by the fact that the use of ultrasonic technology means that significantly fewer or, depending on the material, even no chemicals are required in the liquor. The small size, reduced material usage and shortened process times considerably increase the flexibility of a washing system, so that it can also be used efficiently for smaller production volumes.

Ultrasonic washing is intended to supplement conventional washing of narrow fabrics in particular, but also of broad fabrics with long, temperature-controlled water baths by using energy-saving ultrasonic units.

Technical data

- Ultrasonic technology 20 kHz, per unit 1,000 W

- Sonotrodes up to 200 mm

- Installation of several sonotrodes in parallel - depending on the transport width of the machine

- Throughput speed max. 100 m/min.

- Dimensions approx. 850 mm x 810 mm x 1,280 mm

- Power supply 400 V, 3~N/P/E, 50 Hz

- Compressed air connection 8 bar

Advantages

- Reduction of water consumption

- Reduction of energy consumption

- Washing in "cold" water

- Significant shortening of the washing process

- Only 1-3 passes instead of 4-8

- Less washing distance

- No warm-up times for water or tools

- Increased flexibility

- Reduced use of chemicals

- Compact design

Applications

- Washing out sizing and spinning oils before dyeing

- Washing out of non-fixed dye particles after heat setting

- Narrow fabric

- Broadcloth

- Ropes

- Cords