SONOTRONIC GmbH

Becker-Goering-Str. 17-25

76307 Karlsbad, Germany

E-Mail: sales@sonotronic.de

Mon to Thu 8 am – 5 pm

Friday 8 am – 3 pm

Phone:

Ultrasonic punching

Innovative and combinable technology

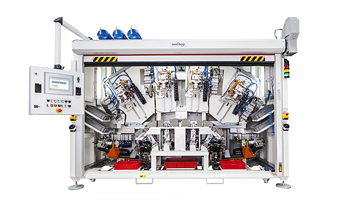

SONOTRONIC's patented ultrasonic punching enables precisely defined openings to be made in plastic parts or textiles in the highest quality. In the automotive sector, ultrasonic punching is suitable for materials such as PP, PP-EPDM, PC/ABS, PC/PBT or composite materials such as textile/PUR, slush/PUR/ABS.

As the developer of ultrasonic punching and the global market leader in this field, we use the technology in special machines for various applications. The automotive industry in particular benefits from this innovation. For example, the openings for parking sensors or headlight cleaning systems can be made directly in the already painted bumpers when punching with radius embossing.

A special design of the sonotrode allows the radius to be embossed directly after cutting. The ultrasonically heated plastic is formed at the cutting edge for this purpose. The result is radius embossing of outstanding optical quality.

During ultrasonic punching, the punched edges of the workpieces are already welded or sealed optically cleanly in outstanding quality.

Advantages

- Reduced punching force due to an ultrasonic-assisted punching die

- No white breakage or fluff formation in the punching surface

- Welding of the edges during punching

- Decoupled, constant radius embossing independent of material thickness

- Optically clean punching for painted and unpainted plastics

- No subsequent changes due to punching of already painted plastics

- Lacquer retention during radius embossing

- Possibility of combining welding and punching tasks, e.g. for sealing and separating packages

- Integration of ultrasonic punching technology into thermoforming packaging processes

Applications

- Exterior applications e.g. apertures on the bumper for parking sensors (PTS), headlight cleaning systems (SRA), side marker lights (SML), trailer coupling (AHK)

- Interior applications e.g. window crank, entrance light, navigation modules

- Ultrasonic punching and welding of bumper covers

- Mesh

- Film

- Nonwoven

- Fabric