In cooperation with Zettl Automotive GmbH, SONOTRONIC Nagel GmbH has developed a production line for the production of mouth and nose protection masks based on ultrasonic. Thanks to the innovative joining technology, protective masks are produced at several manual workstations using the ECO iSONIC ultrasonic welding machines in minute cycles.

At the managing director level, the inquiry came about at the beginning of April in the course of the current COVID-19 pandemic. "The discussions with SONOTRONIC were very professional and uncomplicated. The decisive and decisive factor for the cooperation was, in addition to the specialist knowledge and the necessary flexibility, above all the promise of the short delivery time on the part of the ultrasonic manufacturer," says Reinhard Zettl, Managing Director of Zettl Automotive GmbH.

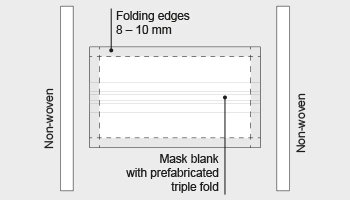

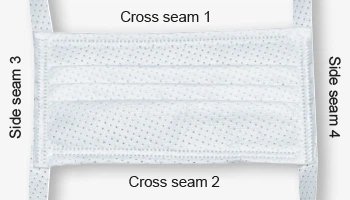

After the initial contact, SONOTRONIC's application engineers visited the plant in Bavaria and, in cooperation with Zettl's developers, the right solution for the welding task was found. With the focus on fast and user-friendly production, the sequence of work steps for the ultrasonic welding was jointly determined. The machines were then designed in order to be able to realize the corresponding number of pieces. For the production of a mask, an ultrasonic series machine ECO iSONIC in the frequency 20 kHz for the cross seams and a 35 kHz machine for the side seams are required. With these machines, Zettl has built up an entire production line and mouth and nose protection masks can be welded manually with ultrasound at minute intervals. The technology is extremely energy and cost-efficient. The ultrasonic welding seams are hard-wearing and resistant, and textile materials such as non-woven as well as other materials can be processed and welded without thread.

Just four working days passed from the first meeting to the delivery of the ultrasonic machines. After commissioning the machines on site, the responsible persons received a complete briefing on machine operation as well as a short training on ultrasonic technology. From then on, the production of the masks is in full swing. Thanks to the intuitive operation of these machines, the user gets fast and optimal welding results even without expert knowledge. This also applies to Zettl. The production of the face masks takes place in only four steps:

- Ultrasonic welding of the horizontal cross seams of the mask blank.

- Manual insertion of the nose clip band.

- Placing the fleece flat bands on the short side of the mask blank.

- Ultrasonic welding of the vertical side seams to fix the fleece flat bands.

Due to the current crisis situation, Zettl Automotive GmbH, a medium-sized company that has been producing interior parts for the automotive industry for over 30 years, has expanded production without further ado by adding ultrasonic series machines. At the company's location in Weng, Lower Bavaria, mouth and nose protection masks have now been produced for the Bavarian government since mid-April 2020.

In view of the current situation, SONOTRONIC Nagel GmbH is proud of the dedication of its employees, especially those working in the field, which is often difficult under these circumstances and can be accomplished under high demands. Managing Director Ingo Nagel is also enthusiastic about the innovative power and the way other companies are dealing with the crisis. "It is nice to see the cohesion of many, even regional entrepreneurs. A crisis literally welds people together."