SONOTRONIC GmbH

Becker-Goering-Str. 17-25

76307 Karlsbad, Germany

E-Mail: sales@sonotronic.de

Mon to Thu 8 am – 5 pm

Friday 8 am – 3 pm

Phone:

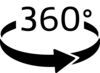

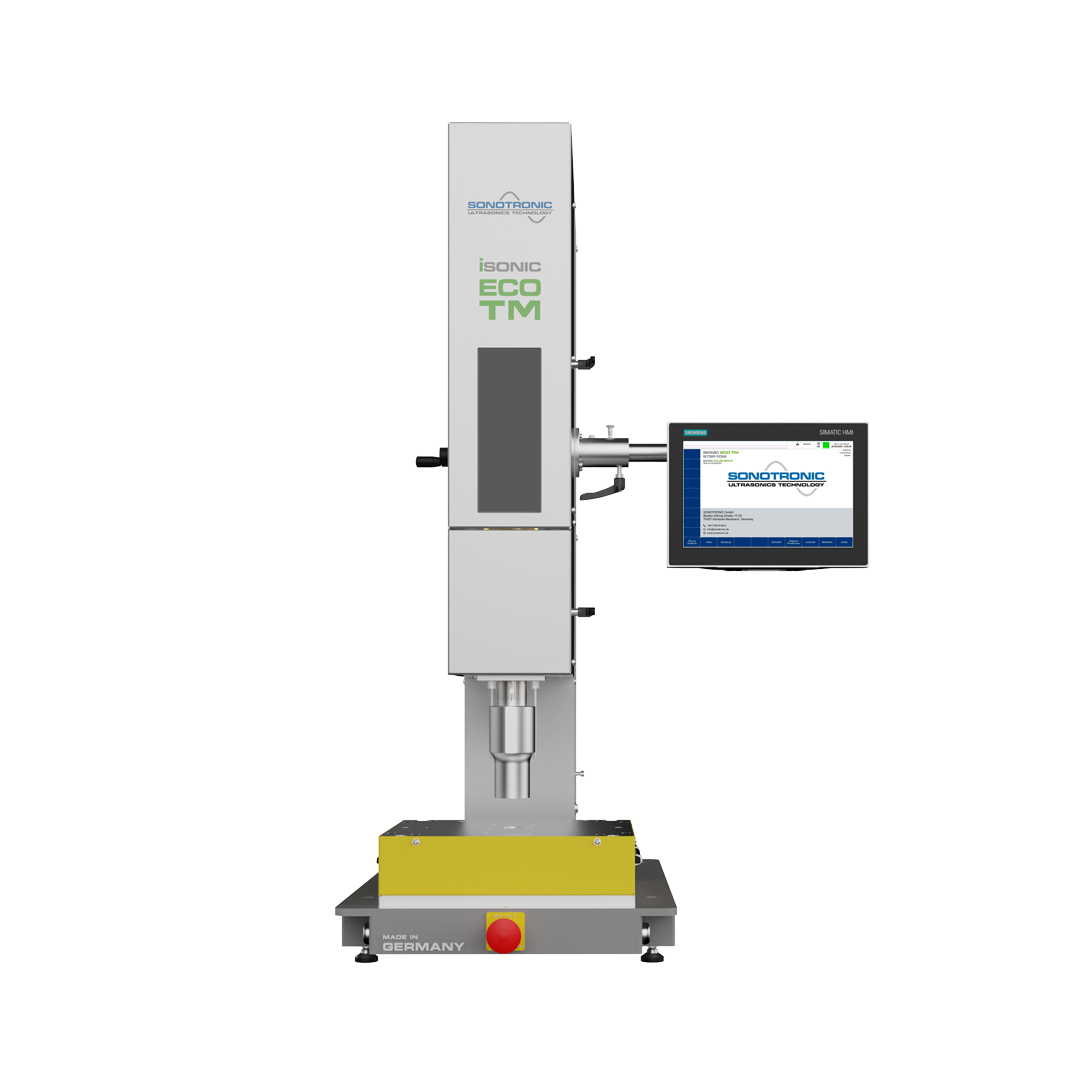

iSONIC ECO TM

Ultrasonic tabletop machine with dual-frequency power

High performance in a compact format – 100% electric, 0% compressed air

Two frequencies, one goal: maximum flexibility in ultrasonic welding

The iSONIC ECO TM is a compact tabletop machine for high-precision ultrasonic applications – 100% electric, maintenance-free and highly versatile. With two integrated frequencies (e.g. 35 kHz and 20 kHz), the machine is ideal for welding, staking, punching and embossing a wide range of materials.

Compact. Modular. Future-ready.

The robust machine concept with a fully electric stepper drive operates entirely without compressed air – for quiet, clean, and energy-efficient production. The external control cabinet saves workspace, while plug-in connections allow for fast commissioning. The 12" HTML5-based touch display offers intuitive operation and freely programmable motion control. Optionally, a Waveshare 9.3" display can be integrated – for an even more detailed representation of all process parameters.

Fully electric, space-saving, ready to use – for modern ultrasonic production

The innovative exchange system for boosters and part fixtures enables quick adaptation to different applications. The iSONIC ECO TM is ideal for industries such as:

Advantages

- 100% electric – no compressed air, no maintenance

- Two ultrasonic frequencies – flexible for different materials

- Modular & mobile – external components, plug-in connections

- Energy-efficient – no warm-up time, low operating costs

- Intuitive operation – 12" touch display with clear visualization

- Compact design – ideal for limited production space

Applications

- Ultrasonic welding of filter media

- Ultrasonic cutting and sealing of textiles

- Ultrasonic welding of housings for electronic components

- Ultrasonic welding of blister packs

- Ultrasonic embossing of logos on plastic parts

- Ultrasonic sealing of drink pouches or infusion bags

- Ultrasonic spot welding of plastic reinforcements

- Ultrasonic welding of automotive interior parts

- Ultrasonic riveting of speaker grilles

- Ultrasonic riveting of trims in household appliances

- Ultrasonic riveting of clips and fasteners

- Ultrasonic riveting of sun visor brackets

Processes

- Ultrasonic

- Hot plate

Standard machine concepts

iSONIC ECOFor you to download

Flyer

Technical data

Video

Accessories I Retrofit

Film feed unit

For welds on visible surfaces. The film transport conveys unused film pieces between the sonotrode and the part, thus preventing damage or markings.

- For protecting sensitive workpiece surfaces against marking

- Can be selected or deselected in the control system

- Individually adjustable to the workpiece

Sliding table

For parts that do not allow direct placement under the sonotrode due to their geometries. The sliding table positions the part under the welding unit.

- For placing high parts under the sonotrode.

- The part size is limited by the sliding table

- Stroke 125 mm

- Can be selected or deselected in the control system

- Clamping plate for plane-parallel alignment of the workpiece

Acoustic protection hood

For small parts with sound-critical applications. The compact and space-saving acoustic protection hood reduces the sound level and is equipped with a safety lift door.

- Reduction of sound emission in accordance with applicable regulations of the Noise Control Ordinance,

Limit value: 80 dB(A) - Pneumatically driven lift door with one-hand start and safety guard

- Front can be swung away for maintenance purposes

- Can be used for component sizes up to max. 300 mm width and 250 mm depth

You might also be interested in

Contact