Only a few streets separate the two high-tech companies in the Karlsbad-Ittersbach industrial area – now they share more than just physical proximity: SONOTRONIC, a specialist in ultrasonic technology, and PartsToGo GmbH, a certified dealer and service provider for industrial 3D printing solutions, are entering into a strategic partnership.

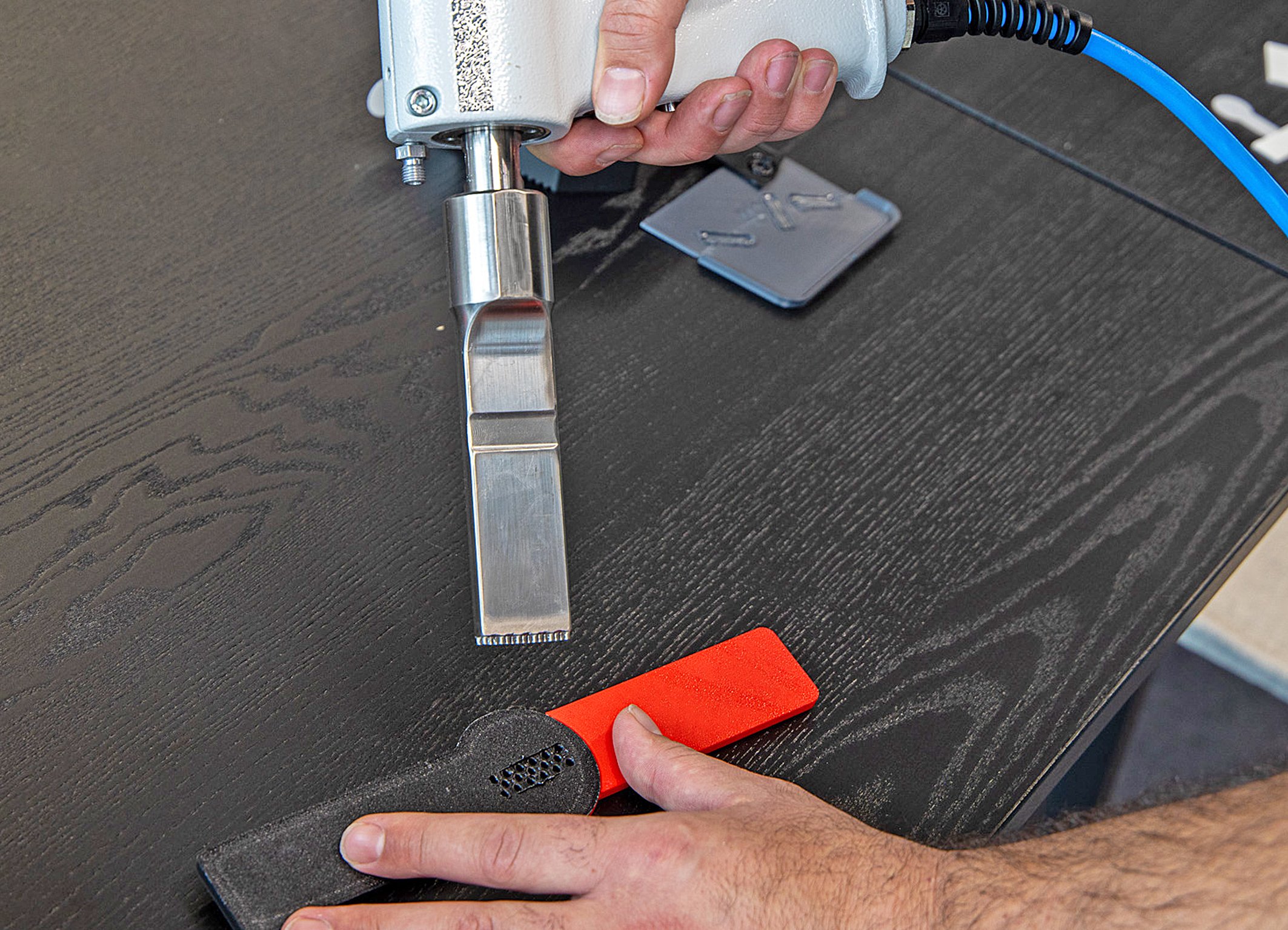

In the future, PartsToGo will rely on the ultrasonic hand welding device iSONIC WAVE HSG from SONOTRONIC for the post-processing of its additively manufactured plastic parts. This technology enables precise, clean, and durable connections – a crucial advantage for applications with high quality requirements.

The official handover of the ultrasonic hand welding device recently took place with Tobias Röcker (CEO PartsToGo) and Manuel Kappler (Application Engineer, PartsToGo) together with Kai Wagner (Sales Manager SONOTRONIC). Even in the first exchange, it became clear that both companies share a passion for innovative technologies as well as for efficient and sustainable manufacturing processes.

Two worlds, one idea: How ultrasonic and 3D-Printing complement each other

While additive manufacturing offers maximum design freedom and flexible production options, ultrasonic processing ensures precise, material-saving, and reproducible connection technology – entirely without additional auxiliary materials. The combination of both technologies enables a seamless process from the digital component to high-quality post-processing.

The ultrasonic technology offers clear advantages:

- Resource- and energy-efficient: Low energy input without complex thermal heating.

- No additives: Connections are made directly in the material – without glue or solvents.

- Clean and fast: Short processing times and low emissions facilitate industrial use.

- High flexibility: The iSONIC WAVE HSG impresses with ergonomic design, quick tool change, and integrated cooling.

- Process reliability: Reproducible results ensure reliable, quality-assured manufacturing.

About PartsToGo GmbH

PartsToGo is an established service provider in the field of additive manufacturing and supports companies with solutions from consulting to production to quality-assured post-processing. With the new partnership, PartsToGo expands its service portfolio to include efficient ultrasonic plastic processing methods and strengthens its position as a modern manufacturing partner. From November 18 to 21, PartsToGo will present itself at Formnext – Where ideas take shape in Frankfurt. Visitors can find the company in Hall 12.1, Stand B119.

From neighborhood to partnership

With the combination of PartsToGo's 3D printing expertise and SONOTRONIC's ultrasonic competence, a forward-looking alliance is created for precise, sustainable, and modern plastic processing.

For you to download

Press Release (EN)