Contact

SONOTRONIC GmbH

Becker-Goering-Str. 17-25

76307 Karlsbad, Germany

E-Mail: sales@sonotronic.de

Mon to Thu 8 am – 5 pm

Friday 8 am – 3 pm

Phone:

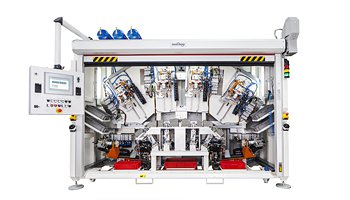

Hot tool machines

Joining technology with high welding strength

Hot tool machines with horizontal or vertical NC axis are suitable for welding large-area joints or double shells on workpieces made of thermoplastics. In hot tool machines, movable heating mirrors weld the workpiece. On request, we design the machines so that the heating mirror and the workpiece fixtures can be changed for different applications.

This machine concept offers various standardized designs, e.g. horizontal or vertical with NC axis, swivel frame and changing device.

Advantages

- Comparison of desired / actual temperature

- Heating current and temperature monitoring

- Facility for sequential setting of the desired temperature

- Password protected parameter settings (several parameter sets possible)

- Setting positions and speeds at the operating panel

- Setting the cleaning cycle at the operating panel

- Option: change concept for heating mirrors and part holders (tool change supported by the operating panel)

- Very high seam strength after cooling

- Compensation of workpiece fluctuations

- Suitable for concealed welded joints

Applications

- Glove box

- Center console

- Double shells

- Large area joins

- Thin-walled parts

- Top shell and bottom shell of an air duct

- Coolant reservoir

- Clean air duct

- Air duct of center consoles

- Sun visor

Processes

- Hot plate welding

- Heat and pressure based manufacturing process

Flexible machine concepts

iSONIC FLEXFor you to download

Flyer

You might also be interested in

Contact